Coal-Activated Carbon with Copper Oxide

Release time:

25-11-05

Source:

This is a specialized type of activated carbon designed for a specific purpose. Here’s a detailed explanation of what it is, how it works, and where it’s used.

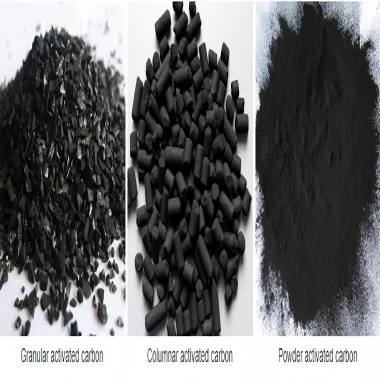

1. The Base Material: Coal-Based Activated Carbon

-

Activated Carbon: This is a highly porous form of carbon with a massive internal surface area (a single gram can have the surface area of a football field). This structure allows it to physically adsorb (trap) molecules on its surface.

-

Coal-Based: The activated carbon is derived from coal (e.g., bituminous coal), which is a common and cost-effective precursor. Coal-based carbon is known for its high hardness and a mix of micro-pores and meso-pores, making it suitable for a variety of gas and liquid phase applications.

2. The Impregnation: “XH-CuO”

This is the most critical part, transforming the carbon from a general adsorbent into a specialized chemical reagent.

-

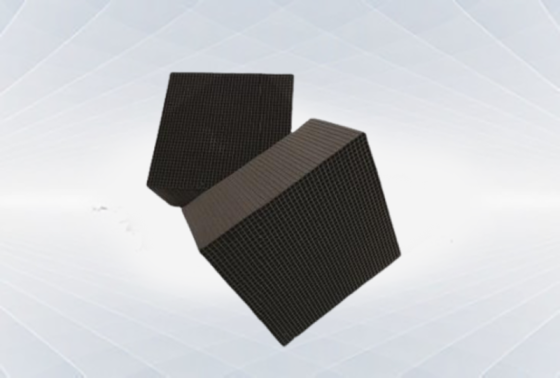

Impregnation: This is a process where the activated carbon is infused with another chemical compound. The porous structure acts as a carrier or support for this compound.

-

XH: This is likely a product code or designation from the manufacturer. “XH” could stand for something like “XinHua” (a company name), “Extra Heavy,” or a specific product line. In the context of safety data, it often signifies that the carbon is impregnated for a specific hazardous gas.

-

CuO: This is the key active ingredient. CuO stands for Copper Oxide (specifically, Copper(II) Oxide).

How It Works: The Synergy

The coal-based activated carbon and the copper oxide work together:

-

Physical Adsorption: The porous carbon structure first traps the target gas molecules from the air stream.

-

Chemical Reaction: Once trapped, the impregnated Copper Oxide (CuO) chemically reacts with the target gas. Copper oxide is particularly effective at oxidizing and neutralizing certain toxic gases.

Primary Application: Gas Mask Filters and Air Purification

Coal impregnated activated carbon XH-CuO is primarily designed for military, industrial, and emergency response use to protect against toxic chemical agents.

The “XH-CuO” formulation is specifically known for its effectiveness against Cyanogen Chloride (CK) and Hydrogen Cyanide (AC).

-

Against Cyanogen Chloride (CK): CuO acts as a catalyst, hydrolyzing CK into less harmful compounds like carbon dioxide and ammonium chloride.

-

Against Hydrogen Cyanide (AC): It can also react with and neutralize hydrogen cyanide.

While its specialty is cyanide-based agents, it also provides broad-spectrum protection against a range of other chemical warfare agents and Toxic Industrial Chemicals (TICs) due to the combined physical adsorption of the carbon and the chemical reactivity of the impregnant.

Other Potential Applications

While its primary use is in respiratory protection, similar copper-oxide-impregnated carbons are used in:

-

Mercury Removal: In coal-fired power plants and industrial processes, impregnated carbons are used to capture toxic mercury vapors from flue gas.

-

Specialized Air Purification: In laboratories or industrial settings where specific gases that react with copper oxide are present.

Key Properties and Considerations

-

Catalytic Action: Unlike some impregnants that get consumed, CuO often acts as a catalyst, meaning it can neutralize multiple molecules without being depleted itself (until the carbon pores become physically blocked).

-

Not for All Gases: It is not a universal impregnation. For example, protection against ammonia or formaldehyde requires carbon impregnated with different chemicals like phosphoric acid or permanganates.

-

Service Life: The filter has a finite service life. It depends on the concentration of the target gas, humidity, and airflow rate. Once saturated or “broken through,” the filter must be replaced.

-

Safety Handling: Used filters can contain concentrated toxic substances and must be disposed of as hazardous waste.

In Summary:

| Feature | Description |

|---|---|

| Base Material | Coal-based Activated Carbon: A hard, porous carbon for physical adsorption. |

| Active Ingredient | Copper Oxide (CuO): A chemical impregnant that neutralizes specific gases. |

| Primary Function | Chemical Reactivity & Adsorption: Traps and chemically destroys target gases. |

| Main Application | Respiratory Protection Filters against chemical warfare agents, especially Cyanogen Chloride (CK) and Hydrogen Cyanide (AC). |

In short, Coal impregnated activated carbon XH-CuO is a high-performance, specialized filtration media designed for life-saving applications where neutralizing specific chemical threats is critical.

CTC

Related News