Why should activated carbon be briquetted?

Release time:

25-11-05

Source:

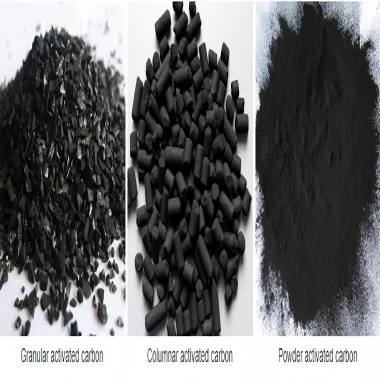

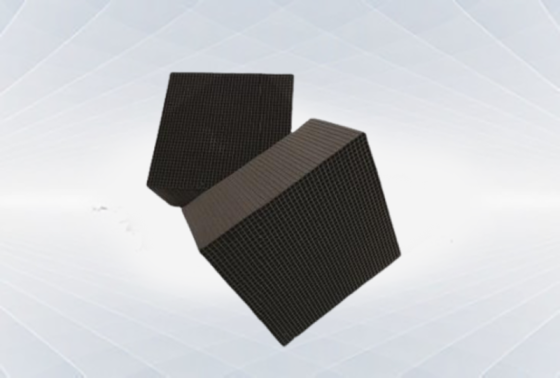

Recently, a customer inquired about activated carbon treatment of pharmaceutical wastewater. During the call, he asked, “With the same iodine adsorption value, which one is better, coal-based granular activated carbon or coal-based briquette activated carbon? The “briquetting forming process” of activated carbon is commonly known as “Agglomeration process” refers to the particle size expansion technology that uses methods such as pressure, stirring, and heating to aggregate and condense fine particulate materials such as dust or powder into larger blocks. The agglomeration process of activated carbon briquettes Purpose: to form fine powder materials into neat particles; to process the fine powder materials collected by the dust collector into a dense, chemically inert final product; to make several components into a uniform mixture; to improve the appearance of consumer goods and highlight their product features; Improve the fluidity of products in silos, feeding devices and other equipment; increase the bulk density of materials by 2 to 10 times; regulate the solubility of products; improve the chemical, energy and metallurgical performance of raw materials; improve the performance of raw materials in Ease of operation in transportation, storage or collection.

CTC

Related News