Introduction of Activated Carbon for Gold Extraction

Release time:

25-11-05

Source:

Introduction: A Revolution in Gold Recovery

The introduction of activated carbon for gold extraction in the late 19th and early 20th centuries was one of the most significant technological advancements in the mining industry. It rendered older, more expensive and dangerous methods (like mercury amalgamation) largely obsolete for large-scale operations and made it economically feasible to process low-grade ores, dramatically reshaping the global gold market.

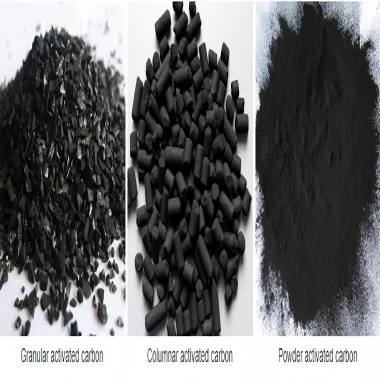

1. What is Activated Carbon?

Activated carbon is a highly porous form of carbon with an enormous internal surface area. A single gram can have a surface area of 500 to 1500 square meters (roughly the size of two football fields). This vast surface area is created through a process of “activation,” where a carbon-rich source material (like coconut shells, coal, or wood) is heated to high temperatures in the presence of steam or chemicals, creating a complex network of microscopic pores.

This structure makes activated carbon an excellent adsorbent—a material that attracts and holds molecules on its surface.

2. The Key Principle: The Adsorption of Gold Cyanide

Modern industrial gold extraction primarily uses a dilute cyanide solution to leach gold from crushed ore. The gold reacts with cyanide and oxygen to form a stable, water-soluble complex ion: Dicyanoaurate ([Au(CN)₂]⁻).

The fundamental role of activated carbon is to adsorb this gold-cyanide complex out of the solution. The positively charged carbon surface attracts the negatively charged [Au(CN)₂]⁻ ions, which then fit perfectly into the carbon’s micropores and are held there by physical and chemical forces.

3. The Main Processes Using Activated Carbon

There are two primary configurations for using activated carbon in gold recovery:

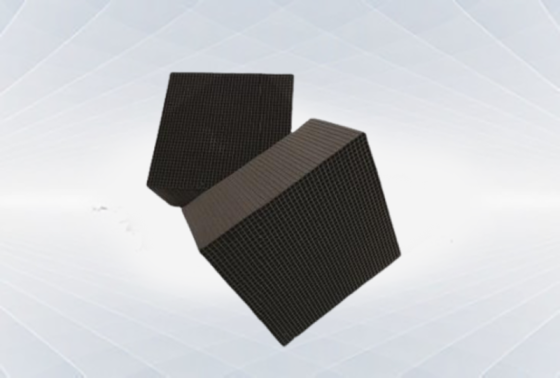

A. Carbon-in-Pulp (CIP)

This is the most common method for treating ores that do not contain carbonaceous material that could prematurely adsorb the gold.

-

Leaching: The crushed ore is mixed with the cyanide solution in a series of large tanks (agitators) to dissolve the gold.

-

Adsorption: After leaching, the ore pulp (a mixture of fine ore particles and solution) is passed through a series of tanks. Each tank contains granules of activated carbon, which is kept suspended by agitators. The carbon moves counter-current to the pulp flow, with the “pregnant” solution (rich in gold) meeting the freshest carbon, and the “barren” solution (depleted of gold) meeting the carbon that is nearly loaded.

-

Separation: The carbon, now loaded with gold, is separated from the pulp using vibrating screens.

B. Carbon-in-Leach (CIL)

CIL is used when the ore contains natural carbon (called “preg-robbing” ore), which would compete with the activated carbon and cause gold losses.

-

Combined Process: In CIL, leaching and adsorption happen simultaneously in the same tank series. Activated carbon is added directly to the tanks where cyanide leaching is occurring.

-

Advantage: The activated carbon adsorbs the gold complex as soon as it is dissolved, “stealing” it away from the natural carbon in the ore, thus preventing gold loss.

4. The Elution and Regeneration Cycle: Getting the Gold Back

Once the activated carbon is loaded with gold, it must be stripped and regenerated for reuse. This is a multi-step process:

-

Acid Washing: The loaded carbon is treated with a hot acid solution to remove inorganic foulants like calcium carbonate scale.

-

Elution (Stripping): The gold is desorbed from the carbon. The most common method is the AARL (Anglo American Research Laboratories) process or the Zadra process. This involves circulating a hot (100-130°C) solution of sodium hydroxide and cyanide through the carbon under pressure. This high-temperature, high-pH environment reverses the adsorption process, stripping the gold off the carbon and into a small, concentrated solution.

-

Electrowinning: The rich eluate solution is pumped through cells containing steel wool cathodes. An electric current is applied, causing the gold (and other metals like silver) to plate out onto the steel wool.

-

Smelting: The steel wool, now coated with gold, is dried, mixed with fluxes, and melted in a furnace at over 1000°C to produce a doré bar of impure gold.

-

Thermal Regeneration: The stripped carbon, now “dead” and fouled with organics, is reactivated in a regeneration kiln. It is heated to ~700°C in a controlled, oxygen-deficient atmosphere to burn off the organic contaminants and restore its porous structure and activity. It is then quenched and ready for another cycle.

5. Advantages of Using Activated Carbon

-

High Efficiency: Capable of recovering over 99% of dissolved gold from solution.

-

Selectivity: It has a strong affinity for the gold-cyanide complex over other base metal complexes.

-

Cost-Effective: The carbon is robust and can be regenerated and reused hundreds of times.

-

Simplicity & Safety: The process is relatively simple to operate and is safer than older methods like zinc precipitation or mercury amalgamation.

-

Handles “Dirty” Solutions: It is more tolerant of impurities like suspended solids compared to other methods.

6. Challenges and Considerations

-

Carbon Attrition: Physical wear and tear cause the carbon to break down into fines, which are lost. This is a major operating cost.

-

Fouling (“Blinding”): Organic compounds, oils, or calcium carbonate can coat the carbon’s surface, blocking the pores and reducing its efficiency.

-

Preg-Robbing Ores: As mentioned, requires the more complex CIL process.

-

Security: The highly valuable loaded carbon must be carefully tracked and secured to prevent theft.

Conclusion

Activated carbon is the workhorse of the modern gold mining industry. Its unparalleled ability to selectively and efficiently capture gold from cyanide leach solutions in a safe, cost-effective, and recyclable manner has made it an indispensable technology. From the CIP/CIL circuits to the elution column and the regeneration kiln, activated carbon is the central pillar that enables the economic extraction of gold on a global scale.

CTC

Related News