How Activated Carbon Enhances Gold Extraction Efficiency

Release time:

25-11-05

Source:

Of course. This is an excellent question that gets to the heart of modern gold processing. Activated carbon is a cornerstone of efficient gold extraction, primarily through a process called Carbon-in-Pulp (CIP) or Carbon-in-Leach (CIL).

Here’s a detailed breakdown of how activated carbon enhances gold extraction efficiency.

The Core Principle: Adsorption

The entire process hinges on one key property of activated carbon: its incredible power of adsorption.

-

Adsorption vs. Absorption: Adsorption is the process where atoms, ions, or molecules (in this case, gold) adhere to the surface of the adsorbent (activated carbon). It’s like a magnet attracting iron filings to its surface. Absorption is when a substance is taken into the structure, like a sponge soaking up water.

-

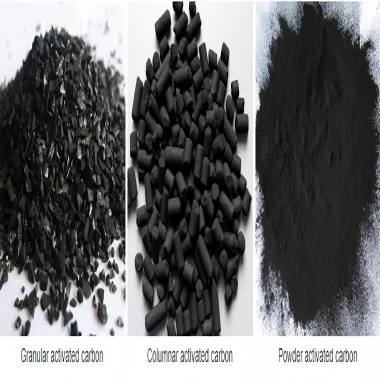

Massive Surface Area: Activated carbon is manufactured to be extremely porous. One gram of activated carbon used in gold recovery can have a surface area of 500 to 1500 square meters—that’s roughly the size of one to three basketball courts! This vast internal surface area provides countless sites for gold to stick to.

The Step-by-Step Process in a CIP/CIL Circuit

Let’s follow the gold from ore to the final product to see where carbon makes its impact.

1. The Starting Point: Leaching

Gold ore is crushed and ground into a fine slurry. A dilute cyanide solution (or other lixiviants) is added. The cyanide reacts with the microscopic gold particles, forming a water-soluble gold-cyanide complex ([Au(CN)₂]⁻). This process is called leaching.

2. The Critical Role of Activated Carbon

The pregnant leach solution (the solution now containing the dissolved gold) is then sent to a series of large tanks. Here is where activated carbon enters the process:

-

Carbon-in-Pulp (CIP): The leached slurry is transferred to adsorption tanks where activated carbon is added.

-

Carbon-in-Leach (CIL): The carbon is added directly to the leaching tanks, combining leaching and adsorption in one step. This is more efficient for certain ores.

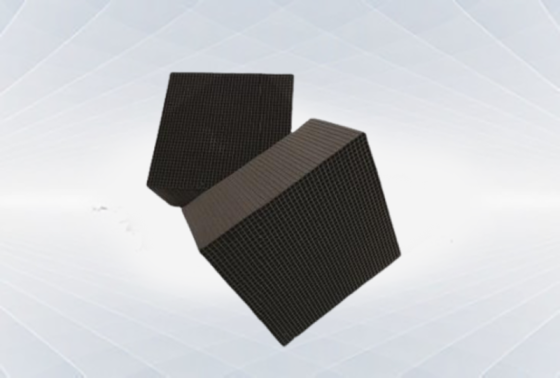

The activated carbon, in the form of coarse granules (1-3 mm), is mixed with the slurry. Due to its specific affinity for the gold-cyanide complex, the [Au(CN)₂]⁻ ions are preferentially adsorbed onto the enormous surface area of the carbon particles.

Why does this happen? The gold-cyanide complex is attracted to the carbon surface through a combination of physical (van der Waals forces) and electrochemical interactions.

3. The Efficiency Advantage: Selective and Continuous Loading

This is where the major efficiency gains are realized:

-

Counter-Current Flow: The slurry flows from one tank to the next, while the activated carbon is moved in the opposite direction. The “fresh” carbon with the highest loading capacity meets the “barren” slurry with the lowest gold concentration. This ensures near-total gold recovery from the solution.

-

Selectivity: Activated carbon has a high affinity for the gold-cyanide complex but a much lower affinity for other dissolved impurities. This means it selectively loads gold, resulting in a purer intermediate product.

-

Concentration Effect: The carbon acts as a “gold sponge,” stripping the gold from a vast volume of dilute solution and concentrating it onto a small volume of carbon. This makes the subsequent steps vastly more manageable and efficient.

4. Elution: Stripping the Gold from the Carbon

Once the carbon is “loaded” with gold (it can hold an impressive amount, often 1000-5000 grams of gold per ton of carbon), it is separated from the slurry. This loaded carbon is then transferred to the elution circuit.

Here, a hot, caustic cyanide solution (or other specialized solutions) is passed through the carbon under pressure. This process reverses the adsorption, desorbing the gold-cyanide complex from the carbon and back into a small, concentrated solution.

5. Electrowinning and Smelting

This small, rich eluate solution is then passed through electrowinning cells, where an electrical current plates the gold out of the solution onto steel wool cathodes. This steel wool is then smelted at high temperatures to produce a pure gold doré bar.

6. Carbon Regeneration

The stripped carbon, now “barren,” is not thrown away. It is thermally reactivated in a kiln (at ~700°C) to burn off any organic foulants and restore its porous structure. It is then quenched and reused in the circuit, making the process highly cost-effective.

Summary: Key Enhancements to Efficiency

| Enhancement | How it Works |

|---|---|

| High Recovery Rate | The counter-current CIP/CIL design and carbon’s high affinity for gold allow for recoveries often exceeding 95-99%. |

| Process Simplicity & Cost-Effectiveness | Eliminates the need for complex and expensive solid-liquid separation steps (like filtration) before gold recovery. |

| Selectivity | Loads gold preferentially over other base metals, leading to a purer product and lower refining costs. |

| Concentration Effect | Takes gold from a huge volume of dilute solution and concentrates it onto a small volume of carbon, making handling and stripping efficient. |

| Reusability | The carbon can be thermally regenerated and reused hundreds of times, drastically reducing operating costs. |

| Robustness | The system is relatively simple to operate and can handle variations in feed grade and composition. |

In conclusion, activated carbon is not just an additive; it is the engine of the modern gold extraction process. Its unique physical and chemical properties enable a highly efficient, selective, and economical method for capturing and concentrating gold from ore, making the large-scale, low-grade gold mining operations of today possible.

CTC

Related News