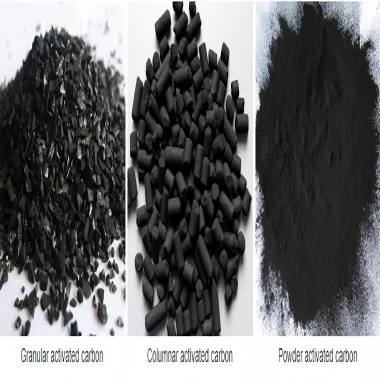

Columnar Activated Carbon

Columnar activated carbon is made of high-quality coal, coconut shell and sawdust through a series of production processe black cylindrical particles are widely used in gas treatment,sewage treatment, desulfurization and denitration, solvent recovery and nitrogen generato-rair separation equipment,painting workshop and other fields in the purification of toxic gases, waste gas treatment,industrial and domestic water purificationtreatment and solvent recovery are also widely used.

Product Details

Product Features

There are 0.9mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 9mm. The length of columnar carbon is generally about 1.5 times its diameter. 9mm columnar activated carbon is usually used as carbon for desulfurization and denitrification (also known as activated coke or large particles in the industry)

Product Applications

Columnar activated carbon is widely used in the purification of toxic gases, waste gas treatment, industrial and domestic water purification, and solvent recovery.

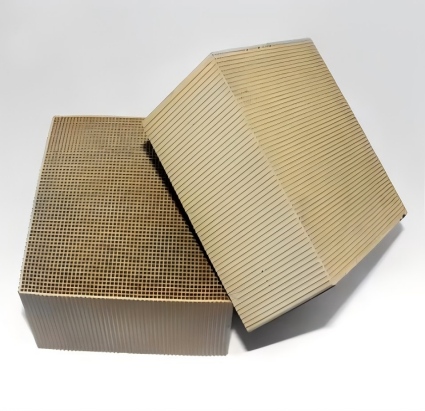

Columnar activated carbon is applied in various aspects of industrial and agricultural production, such as: alkali-free deodorization (refining and desulfurization) in the petrochemical industry, ethylene desalination (refining filler), catalyst carriers (palladium, platinum, rhodium, etc.), water purification and wastewater treatment; power plant water treatment and protection in the power industry; chemical catalysts and carriers, gas purification, solvent recovery, and decolorization and refining of oils and fats in the chemical industry; refining and decolorization of beverages, wines, monosodium glutamate mother liquor, and food in the food industry; gold extraction and tailings recovery in the gold industry; wastewater treatment, waste gas and harmful gas treatment, and gas purification in the environmental protection industry; and related industries such as cigarette filters, wood flooring moisture-proofing, odor absorption, automotive gasoline evaporation pollution control, and the preparation of various impregnating agents. Activated carbon has excellent development prospects and a broad sales market in the future.

Product Parameters

Product Parameters

Note: it can be supplied according to the special requirements of users

| Index

Model |

Water Content | Strength | Ash | Iodine Value | C.T.C | Filling Density | Particle Size |

| % | % | % | mg/g | % | g/L | nm | |

| AM-3070 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 2.0 |

| AM-4070 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 3.0 |

| AM-4075 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 3.0 |

| AM-8×30 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 2.4-0.5 |

| AM-12×40 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 1.5-0.44 |

| AM-8×16 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 2.4-1.1 |

| PK-8×12 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 3.4-1.5 |

| AM-25×50 | ≤5 | ≥97 | ≤4 | ≥400-1100 | 50-80 | 400-550 | 0.2-0.70 |

Advantages of Columnar Activated Carbon

As high-quality sawdust and coconut shell are used as raw materials, the columnar activated carbon produced has lower ash content, less impurities, gas adsorption value and absolute advantage over traditional coal columnar carbon.

Coal columnar activated carbon has the advantages of developed pore structure, large specific area, strong adsorption capacity, high mechanical strength, small bed resistance, good chemical stability, easy regeneration, durability,etc.

The pore size distribution of the product is reasonable, achieving maximum adsorption and desorption, greatly improving the service life of the product(average 2-3 years), which is 1.4 times that of ordinary coal based carbon.

Columnar Activated Carbon Applicability

① Gas phase adsorption;

② Organic solvent recovery(benzene gas toluene, acetone recovery in the acetate fiber industry);

③ Removal of impurities and harmful gases, waste gas recovery;

④ Excessive gasoline recovery in refineries, gas stations,and oil depots;

⑤ Used for catalytic removal of hcl from tetrachl oroethane to prepare trichloroethylene using activated carbon.